Hockey sticks are more than just tools of the trade for players; they’re emblematic of the sport’s evolution over the years. From humble beginnings as wooden implements to cutting-edge composite constructions, the hockey stick has undergone a remarkable transformation. In this post, we delve into the rich history of the hockey stick, exploring its materials, evolution, and impact on the game.

Wooden Beginnings:

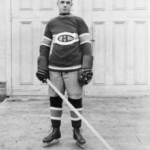

In the early days of hockey, sticks were primarily crafted from wood. Hickory and ash were the predominant choices due to their strength and flexibility. Hickory, known for its durability, was favored for its ability to withstand the rigors of gameplay, while ash offered a lighter alternative, prized for its responsiveness on the ice.

As the sport gained popularity and technology advanced, manufacturers began experimenting with different wood types and stick designs to optimize performance. However, wooden sticks remained the standard for decades, shaping the way the game was played.

Hockey Tidbit: In the NHL a player will use an average of 60 to 120 sticks per season while a junior or Collage player will use about 25 per season.

Transition to Composite:

The turning point in hockey stick technology came with the introduction of composite materials. In the 1980s, companies started producing sticks made from materials such as fiberglass, graphite, and carbon fiber. These composites offered several advantages over traditional wooden sticks, including increased strength, lighter weight, and enhanced flexibility.

Carbon fiber emerged as a game-changer in stick construction, revolutionizing the way players approached the game. Its unparalleled strength-to-weight ratio allowed for the creation of sticks that were both incredibly lightweight and incredibly durable. This innovation paved the way for a new era of performance-driven hockey equipment.

Hockey Tidbit: An NHL team can spend as much as $500,000 per year on sticks. YIKES!!!

Today’s Composite Sticks:

Modern composite hockey sticks are a far cry from their wooden predecessors. They are meticulously engineered using advanced manufacturing techniques to optimize performance and durability. Carbon fiber remains a primary component, often combined with other materials such as fiberglass or Kevlar to fine-tune characteristics like flex and feel. Today’s composite sticks are designed to give players consistent shots with maximum power and accuracy.

Composite sticks offer players a level of customization and performance that was once unimaginable. With various flex profiles, blade patterns, and kick points to choose from, players can tailor their sticks to suit their playing style and preferences. This level of versatility has transformed the way the game is played at all levels, from amateur leagues to the professional ranks..

Production and Pricing:

The production of hockey sticks is a massive industry, with millions of sticks manufactured each year to meet the demands of players worldwide. Major brands like Bauer, CCM, and Warrior dominate the market, producing a wide range of sticks to cater to players of all ages and skill levels.

While wooden sticks are still available for nostalgic purposes or recreational play, composite sticks have become the standard choice for serious hockey players. Prices for composite sticks vary depending on factors such as brand, model, and technology. Entry-level sticks can be found for as low as $50-$100, while top-of-the-line models used by professional players can exceed $300

Conclusion: The evolution of the hockey stick from wood to composite is a testament to the relentless pursuit of innovation within the sport. What began as a simple wooden implement has evolved into a high-tech piece of equipment that has revolutionized the game of hockey. As technology continues to advance, it’s exciting to imagine what the future holds for this essential piece of hockey equipment.